Copyright © 2006 Manhattan LTD / L.L.C , All rights reserved International copyright laws apply to all content

Pipes

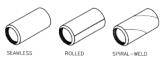

We supply and stock seamless and welded pipes from 1/8” upto 80” in all grade. Our delivery and stock program covers high specification standards, and includes following grades.

Manhattan Trading LTD / L.L.C

American Society for Testing:

ASTM A53 :

Standard Spec. for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless .

1.

Scope:

1.1

This

specification

covers

seamless

and

welded

black

and

hot-dipped

galvanized

steel

pipe

in

NPS

1/8

to

NPS

26

[DN

6

to

DN

650]

(Note

1),

inclusive,

with

nominal

wall

thickness

(Note

2)

as

given

in

Table

X2.2

and

Table

X2.3.

It

shall

be

permissible

to

furnish

pipe

having

other

dimensions

provided

that

such

pipe

complies

with

all

other

requirements

of

this

specification.

Supplementary

requirements of an optional nature are provided and shall apply only when specified by the purchaser.

Note

1

.

The

dimensionless

designators

NPS

(nominal

pipe

size)

[DN

(diameter

nominal)]

have

been

substituted

in

this

specification

for

such

traditional

terms

as

"nominal

diameter,"

"size,"

and

"nominal size."

Note

2.

The

term

nominal

wall

thickness

has

been

assigned

for

the

purpose

of

convenient

designation,

existing

in

name

only,

and

is

used

to

distinguish

it

from

the

actual

wall

thickness,

which

may

vary over or under the nominal wall thickness.

2. Referenced Documents:

A90/A90M

Test

Method

for

Weight

[Mass]

of

Coating

on

Iron

and

Steel

Articles

with

Zinc

or

Zinc-Alloy

CoatingsA370

Test

Methods

and

Definitions

for

Mechanical

Testing

of

Steel

ProductsA530/A530M

Specification

for

General

Requirements

for

Specialized

Carbon

and

Alloy

Steel

PipeA700

Practices

for

Packaging,

Marking,

and

Loading

Methods

for

Steel

Products

for

ShipmentA751

Test

Methods,

Practices,

and

Terminology

for

Chemical

Analysis

of

Steel

ProductsA865

Specification

for

Threaded

Couplings,

Steel,

Black

or

Zinc-Coated

(Galvanized)

Welded

or

Seamless,

for

Use

in

Steel

Pipe

JointsB6

Specification

for

ZincE29

Practice

for

Using

Significant

Digits

in

Test

Data

to

Determine

Conformance

with

SpecificationsE213

Practice

for

Ultrasonic

Testing

of

Metal

Pipe

and

TubingE273

Practice

for

Ultrasonic

Examination

of

the

Weld

Zone

of

Welded

Pipe

and

TubingE309

Practice

for

Eddy-Current

Examination

of

Steel

Tubular

Products

Using

Magnetic

SaturationE570

Practice

for

Flux

Leakage

Examination of Ferromagnetic Steel Tubular ProductsE1806 Practice for Sampling Steel and Iron for Determination of Chemical

ASTM A106 :

Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service

1.

Scope

;

1.

1

This

specification

covers

seamless

carbon

steel

pipe

for

high-temperature

service

(Note

1)

in

NPS

1/8

to

NPS

48

[DN

6

to

DN

1200]

(Note

2)

inclusive,

with

nominal

(average)

wall

thickness

as

given

in

ASME

B36.10.

It

shall

be

permissible

to

furnish

pipe

having

other

dimensions

provided

such

pipe

complies

with

all

other

requirements

of

this

specification.

Pipe

ordered

under

this

specification

shall

be

suitable

for

bending,

flanging,

and

similar

forming

operations,

and

for

welding.

When

the

steel

is

to

be

welded,

it

is

presupposed

that

a

welding

procedure

suitable

to

the

grade

of

steel and intended use or service will be utilized.

Note 1:

It is suggested, consideration be given to possible graphitization.

Note

2

:

The

dimensionless

designator

NPS

(nominal

pipe

size)

[DN

(diameter

nominal)]

has

been

substituted

in

this

standard

for

such

traditional

terms

as

"nominal

diameter",

"size",

and

"nominal

size".1.2

Supplementary

requirements

of

an

optional

nature

are

provided

for

seamless

pipe

intended

for

use

in

applications

where

a

superior

grade

of

pipe

is

required.

These

supplementary

requirements

call

for

additional

tests

to

be

made

and

when

desired

shall

be

so

stated

in

the

order.1.3

The

values

stated

in

either

SI

units

or

inch-pound

units

are

to

be

regarded

separately

as

standard.

The

values

stated

in

each

system

may

not

be

exact

equivalents.

Therefore,

each

system

is

to

be

used

independently

of

the

other.1.4

The

following

precautionary

caveat

pertains

only

to

the

test

method

portion,

Sections

11,

12,

and

13

of

this

specification:

This

standard

does

not

purport

to

address

all

of

the

safety

concerns,

if

any,

associated

with

its

use.

It

is

the

responsibility

of

the

user

of

this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Carbon Steel :

A53 grade A + grade B

P235

A106 grade B + grade C

P265 Wst. 1.4301

A333 grade 3 + grade 6

P265NLWst. 1.4401

API 5L grade B / X42 /X52 /X60 / X65 /X70

P355 - P460 Wst. 1.4541

Carbon steel is more commonly used :

Than

any

other

metal,

and

has

long

been

admired

for

its

versatility

and

low

cost.

Federal

Steel

stocks

a

complete

selection

of

carbon

steel

pipe

and

steel

tubing

in

an

extraordinary

range

of

grades

and

specifications.

Seamless

steel

pipe

and

tubing

is

stocked

in

outer

diameters

(OD’s)

through

36”,

ERW

(Electric

Resistance

Welded)

pipe,

including

rolled

and

welded

pipe

and

spiral

weld

pipe,

is

stocked

in

OD’s

through

60”.

As

a

specialist

in

schedule

and

non-schedule

heavy

wall

pipe

and

tubing,

Federal

Steel

inventories

multiple

specifications,

including

API

5L

(X-

grades),

ASTM

(A106

,

A53

,

A519,

A513

Type

5

DOM), and ASME specifications.

Alloy Steel:

A335 grade P1

16 Mo3

A335 grade P5

13CrMo45

A335 grade P9

10CrMo9-10

A335 grade P11/P12 X10CrMoVNb9-1

A335 grade P22

A335 grade P91

The benefits of alloy steel pipe:

The

benefits

of

alloy

steel

pipe

include

its

tensile

strength,

yield

strength,

fatigue

resistance,

toughness,

and

wear

resistance.

As

suppliers

of

seamless

and

welded

alloy

steel

pipe,

Federal

Steel

specializes

in

'chrome

moly'

SA335

piping

in

grades

P5,

P9,

P11,

P22,

and

P91.

Chrome

moly

power

piping

is

used

extensively

in

power

plants

throughout

the

world.

In

addition

to

SA335,

other

specifications

we

offer

include

A519

and

rolled

and

welded

pipe

in

A-691.

Alloy

piping

products

are

available

in

outer

diameters

through

60”

(OD)

and up to 4” wall thickness. -

Stainless Steel:

A312 / A358

TP304 (L/H)

UNS S 30400

WSt. 1.4301

A312 / A358

TP316 (L/H/Ti) UNS S 31600

WSt. 1.4401

A312 / A358

TP321 (H)

UNS S 32100

WSt. 1.4541

A312 / A358

TP347 (H)

UNS S 34700

WSt. 1.4550

A790

6 Mo

UNS S 31254

WSt. 1.4529

A790

Duplex

UNS 31803 WSt. 1.4462

A790

Super Duplex UNS S 32750 WSt. 1.4501

A790

Super Duplex UNS S 32760

WSt. 1.4501

To answer the question “Why Stainless Steel?

these and other beneficial properties of the Mo containing stainless

steels are summarized as follows:

Excellent

corrosion

resistance

-

SS

are

significantly

more

resistant

to

oxidation

by

water

and

biocides

than

carbon

steel

and

cast

or

ductile

iron. This results in longer life time for pipelines.

Corrosion

protection

–

an

internal

and

external

coating

is

not

required

for

SS,

nor

is

cathodic

protection.

This

reduces

system

cost

and

makes

stainless steels more compatible with environment.

Hygienic

materials

-

due

to

their

very

high

passive

film

stability,

SS

are

basically

inert

in

waters.

Leaching

of

alloying

elements

(Cr

and

Ni)

is

within

safe

limits.

As

a

result,

they

provide

a

better

quality

of

drinking

water.

Pipes :